The Technical Precision of Cutting 304 Stainless Steel

304 stainless steel is one of the most widely used materials in various industries due to its excellent corrosion resistance, durability, and strength. Cutting this robust metal, however, requires skill, advanced technology, and proper equipment to achieve precise results. The technical requirements for cutting 304 stainless steel are high, as this material’s properties can pose significant challenges.

1.Characteristics of 304 Stainless Steel

304 stainless steel is an austenitic stainless steel that contains chromium and nickel, which contribute to its impressive corrosion resistance and strength. Its non-magnetic nature and work-hardening properties make it challenging to cut using traditional methods. Additionally, it can retain heat during cutting processes, which could affect the metal’s structure and finish if not properly controlled.

2.Cutting Techniques for 304 Stainless Steel

Several cutting methods are suitable for 304 stainless steel, each requiring specialized technology and expertise. Here are some commonly used methods:

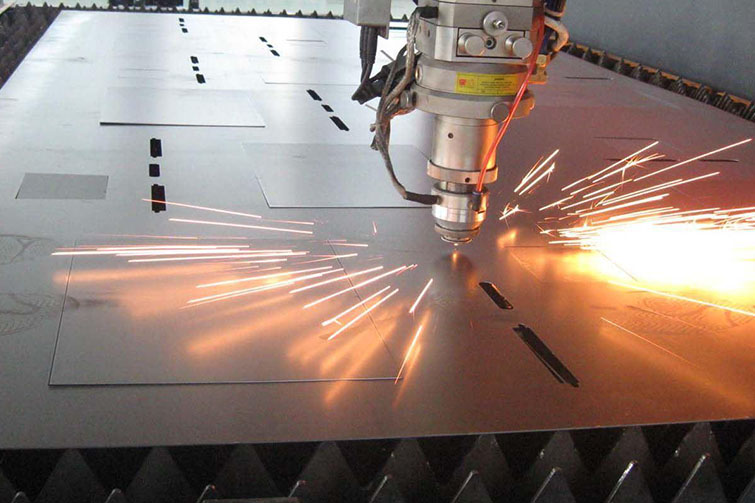

Laser Cutting Laser cutting is a preferred method for 304 stainless steel due to its high precision and clean finish. A focused laser beam heats the material to the point where it melts or vaporizes, allowing for intricate cuts with minimal heat-affected zones (HAZ). However, laser cutting requires careful control of parameters like laser power, speed, and focus to avoid material warping. Operators must also manage the assist gas, typically nitrogen or oxygen, which influences the cut’s quality.

Plasma Cutting Plasma cutting is another effective technique for cutting thicker sheets of 304 stainless steel. In this process, an electrical arc generates a stream of plasma that melts the metal and removes it. While plasma cutting can cut stainless steel with ease, achieving precision requires skill in controlling arc current, torch speed, and gas flow.

Water Jet Cutting Water jet cutting is known for its cold cutting process, which avoids heat-related distortions. Using a high-pressure stream of water mixed with abrasive materials, water jet cutting provides precision without altering the material’s properties. This method requires high-quality equipment to maintain pressure and deliver accurate cuts.

Mechanical Cutting (Sawing, Milling, and Shearing) Mechanical cutting techniques like sawing, milling, and shearing are also employed for 304 stainless steel, particularly for thicker sections. Due to its toughness, stainless steel can quickly wear down tools, so carbide-tipped tools or high-speed steel saws are typically required. Proper cooling and lubrication are essential to reduce tool wear and maintain cut quality.

3.Challenges and Technical Expertise Required

Cutting 304 stainless steel presents several technical challenges, primarily due to its hardness, toughness, and heat retention properties. Here are key aspects that contribute to the high technical requirements for cutting this material:

- Precision Control: Achieving a clean cut requires expertise in managing cutting speeds, heat input, and cooling methods.

- Tool Wear Management: The hardness of stainless steel can cause tools to wear out quickly, so regular maintenance and replacement of cutting tools are necessary.

- Heat Management: Effective heat management is crucial, especially in methods that involve high temperatures, as excessive heat can affect the material's strength and corrosion resistance.

- Surface Quality: For applications where surface finish is important, cutting techniques must be fine-tuned to avoid rough edges or discoloration.

Conclusion

The high technical requirements for cutting 304 stainless steel stem from its unique properties, which demand precise control, advanced equipment, and expert knowledge. Cutting methods like laser cutting, plasma cutting, and water jet cutting each offer specific advantages, but all require skilled handling to achieve optimal results. Whether for industrial, architectural, or specialized applications, the precision involved in cutting 304 stainless steel underscores the importance of skilled operators and reliable technology.