The Versatility of Stainless Steel Cutting Products

Stainless steel cutting products have become indispensable across various industries due to their strength, corrosion resistance, and versatile applications. Stainless steel is a popular choice for projects requiring durability and a high-quality finish. Cut stainless steel components offer reliable performance in environments ranging from construction and healthcare to automotive and food processing. Here’s an overview of how stainless steel cutting products are used extensively across multiple sectors.

Key Advantages of Stainless Steel Cutting Products

Stainless steel cutting products provide several benefits that make them widely applicable:

- Durability: Stainless steel is highly resistant to rust, corrosion, and staining, which gives it a long lifespan even in harsh conditions.

- Cleanliness and Hygiene: Stainless steel is easy to clean and sterilize, which is crucial for industries like healthcare and food production.

- Aesthetic Appeal: Stainless steel has a modern, clean appearance, making it a favorite in architectural applications.

- Sustainability: Stainless steel is 100% recyclable, which adds to its appeal for eco-conscious industries.

Industries and Applications

Construction and Architecture In construction, stainless steel cutting products are integral to both structural and aesthetic elements. They are used in beams, railings, and fixtures due to their high strength and resistance to corrosion. Architects appreciate stainless steel’s sleek look and versatility, which allows it to be shaped into complex designs for facades, sculptures, and handrails.

Automotive and Aerospace The automotive and aerospace sectors rely heavily on precision-cut stainless steel components. For these industries, the durability, heat resistance, and weight-to-strength ratio of stainless steel are invaluable. Stainless steel is often used in exhaust systems, fuel tanks, and structural parts, contributing to vehicle longevity and efficiency.

Medical and Healthcare Stainless steel cutting products are highly preferred in healthcare environments where sanitation and durability are essential. Surgical instruments, tables, and carts are often made of stainless steel because it is easy to sterilize and maintains a clean surface. Additionally, stainless steel’s non-reactive nature makes it suitable for medical implants and devices that require biocompatibility.

Food and Beverage Industry In food processing, stainless steel cutting products are used for equipment that handles food, such as countertops, tanks, and conveyors. Stainless steel is favored in this industry due to its resistance to corrosion from acidic foods, ease of cleaning, and ability to withstand high temperatures.

Energy and Utilities Stainless steel is crucial for power generation and other utilities, especially in renewable energy sectors like solar and wind, where components are exposed to harsh outdoor environments. Components made from stainless steel, such as turbines, pipelines, and fuel tanks, benefit from its durability and resistance to rust, extending the lifespan of critical infrastructure.

Home and Consumer Goods Stainless steel cutting products are also widespread in home appliances and consumer goods. From kitchen appliances like refrigerators, ovens, and dishwashers to small items like cutlery and water bottles, stainless steel’s clean appearance and low maintenance requirements make it ideal for daily-use products.

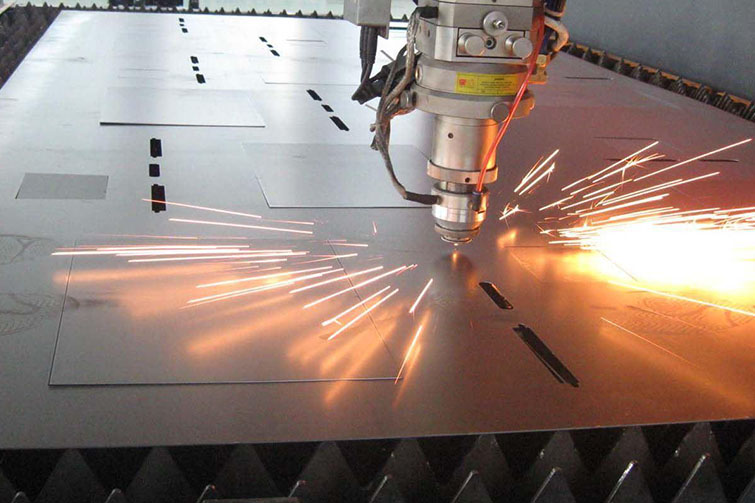

Techniques for Cutting Stainless Steel

Various cutting techniques, including laser cutting, water jet cutting, plasma cutting, and mechanical cutting, are used to shape stainless steel products for these applications. Each technique offers distinct advantages, such as laser cutting’s precision for intricate designs or water jet cutting’s ability to avoid heat-related warping.

Conclusion

The widespread use of stainless steel cutting products across diverse industries highlights stainless steel’s versatility and reliability. Whether in industrial machinery, medical equipment, or everyday household items, stainless steel’s durability and aesthetics contribute to its growing demand. As new cutting technologies continue to evolve, stainless steel’s role in innovative design and high-performance applications will likely expand, making it a critical material in modern manufacturing and beyond.